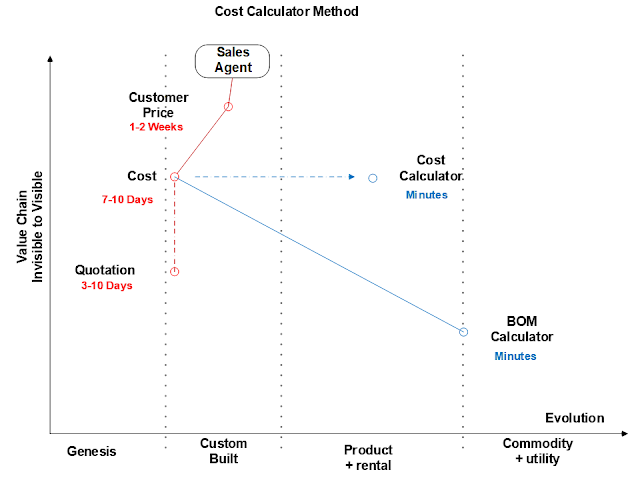

Wardley Mapping (Value Chain Mapping) can be a great asset in describing the evolution of a business process. In this case, I'm going to illustrate the changes of the Costing and Pricing action to show how improvements may be identified once the current or base activity is mapped.

In this scenario, Costing and Pricing, a sales agent needs to arrive at a Price for the customer.

The process includes engagement of a high skill technical person to create a Bill of Materials (BOM) for the customer.

It requires a Quotation that includes all of the BOM items, this is then used to create a Cost.

The Costs are then all rolled up, margin/cost-of-money and services/labor are included to create Customer Price in such a way that the Sales Agent may have a Rough Order of Magnitude (ROM) conversation with the Customer.

Here's what that map looks like.

|

| 1. Costing and Pricing Activity |

Keeping in mind that Wardley Map placement is relative, BOM activity is in the Genesis category primarily because "we know very little" about the customer desire until a BOM is generated to discuss and modify to the customer requirements.

Quotation is in Custom Build, because it is generated uniquely based on the BOM for the customer. It is subject to change, also based on customer requirements.

The same can be said for Cost and Customer Price. Without a customer qualified BOM, the entire process flow is subject to correction and reset until that action is completed.

The Question to ask, "Can we move this process to Product or Utility?"

|

| 2. Optimize the BOM activity |

Any one of the items in the process flow could be looked at for possible improvement. In determining where to start, sometimes it is just picking a point and mapping out possible evolution steps and see what happens to the map.

In this case, we're looking at the BOM, if for no other reason than it feeds the more visible aspects of the value chain.

The Question for BOM, "Can we improve the BOM by creating a calculator for the BOM?"

There are some implications to this question, the principle one, can we create a standard method. The standard method would be an idealization of the Bill of Materials in such a way that changes to it became mathematical multiples of or well understood relationships between the elements. This implies a standard and baseline awareness of a design or architecture that at the very smallest level that consists of units that can be both measured and used as incremental building blocks.

|

| 3. New BOM Method |

In the case where that is true, the Bill of Materials Calculator (figure 3) can potentially replace the BOM action in Genesis. Utilizing well understood units of measure, the calculator makes it possible to manipulate the BOM output to the customer desired goals/end-state much more rapidly. The output of this tooling is arguably a utility in nature, but because it continues to rely on manual understanding/input, we'll put it squarely on the product/utility line.

The benefit of this change in process, we've shaved 7-14 days off the Process.

The Question for BOM Calculator, "How important is the Quotation?"

As it turns out, the Quotation with the source suppliers is only required when finalizing a deal with the customer. So, as figure 4 indicates, we're going to skip over Quotation and start to consider the Cost analysis. Because supply chain / purchasing requires the Quotation, we cannot remove it from the process, but it doesn't have to be done until we're in a position to make a purchase.

|

| 4. Quotation |

With Quotation removed (for the moment), and a good awareness of the BOM sizing activity we'll tie the BOM directly to the Costing activity.

The benefit of this change in process, we don't have to Quote each an every time we need to understand a Rough Order of Magnitude (ROM) cost.

The Question for the BOM Calculator mechanism then becomes, "Can we get to ROM cost quicker if we understand the BOM?"

In the

next installment, I'll review how Costing evolves to improve the process.